Metal Laser Cutting

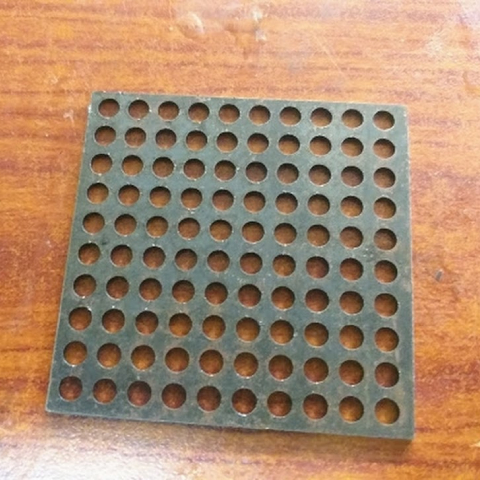

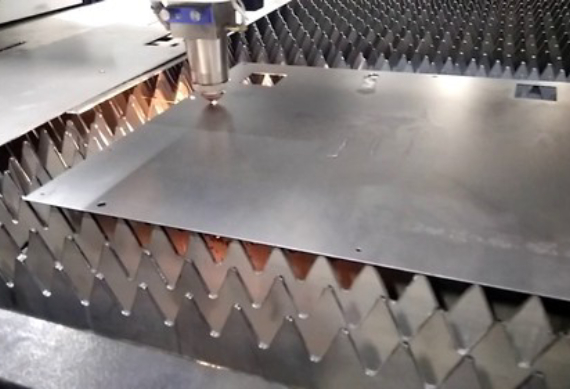

Metal laser cutting is a process that uses a high-powered laser beam to cut through various types of metal materials. The laser beam is created by a laser generator and is focused by a lens or mirrors to concentrate its energy onto a small spot. As the laser beam moves across the metal surface, it melts or vaporizes the material and creates a cut.

The process of metal laser cutting can be either CNC (computer numerical control) or manual, depending on the complexity of the design and the level of precision required. CNC metal laser cutting involves programming the laser cutter with a computer to follow a specific cutting pattern or design. This method is commonly used in industrial settings and can produce intricate shapes and cuts with high precision.

Manual metal laser cutting, on the other hand, is typically used for smaller projects and involves manually guiding the laser beam across the metal surface to create a cut. While this method is less precise than CNC laser cutting, it can still produce accurate cuts and is more cost-effective for smaller projects.

Metal laser cutting is commonly used in various industries such as automotive, aerospace, and manufacturing. It is suitable for cutting various types of metals, including steel, aluminum, brass, and copper. The process is efficient, fast, and produces clean cuts with minimal waste, making it a popular choice for metal fabrication.

© Copyright 2025 Al Najma Factory All Rights Reserved. Designed By: OnDigma InfoTech