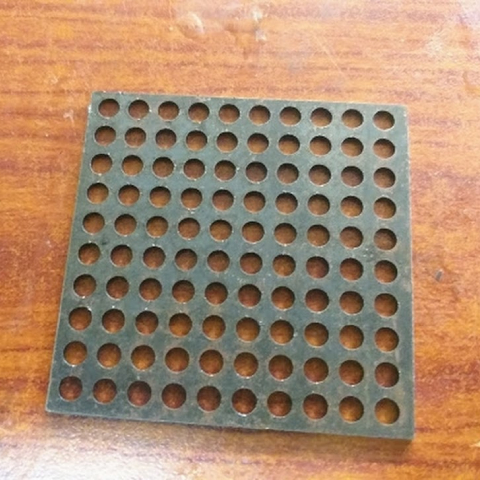

Fabrication Work

Fabrication work refers to the process of shaping, cutting, and joining metal materials to create custom parts, structures, or products. It involves using various techniques such as cutting, bending, welding, and machining to transform raw metal materials into functional components or finished products.

The fabrication process typically begins with a design or blueprint, which specifies the desired size, shape, and functionality of the finished product. The metal materials are then selected and prepared for fabrication, which may involve cutting them into specific shapes and sizes using cutting tools such as saws, lasers, or plasma cutters.

Bending equipment such as press brakes or rollers are then used to bend the metal materials to the desired angle or radius, while welding equipment is used to join the metal components together. Machining processes such as drilling, tapping, or milling may also be used to create precise holes, threads, or other features on the metal surface.

Once the fabrication work is complete, the finished product is typically inspected and tested to ensure that it meets the required specifications and quality standards. Fabrication work is commonly used in industries such as construction, aerospace, automotive, and manufacturing to create a wide range of products, including structural components, machinery, tools, and consumer products.

Overall, fabrication work is a complex process that requires specialized skills, knowledge, and equipment to transform raw metal materials into functional and high-quality components or products that meet the specific needs of various industries and applications.

© Copyright 2025 Al Najma Factory All Rights Reserved. Designed By: OnDigma InfoTech